TERRANAUT

ADDITIVE MANUFACTURING

Unveiling the 3D Printing Wonderland: A Journey Through Diverse Dimensions!

"Creativity is piercing the mundane to find the marvelous."-Bill Moyers

Welcome to the world of 3D printing, also known as additive manufacturing, a revolutionary technology that has transformed the way we design, create, and manufacture objects while opening up new possibilities for innovation. This blog post serves as your comprehensive guide to understanding the different types of 3D printing technologies and their applications. From basic hobbyist models to advanced industrial systems, let's dive into the diverse world of 3D printing.

1. Fused Deposition Modeling (FDM):

Fused Deposition Modeling (FDM) is one of the most popular and accessible 3D printing methods. This technique involves melting a thermoplastic filament and extruding it layer by layer to build the desired object. some of the thermoplastic filaments include PLA, ABS, PETG, TPU, PVA, and more. FDM printers are widely used for rapid prototyping, DIY projects, and educational purposes due to their affordability and ease of use. However, they may have limitations in producing high-resolution and intricate models.

2. Stereolithography (SLA):

Stereolithography (SLA) was one of the first 3D printing technologies invented. SLA printers utilize a liquid photopolymer resin that solidifies when exposed to UV light. A UV laser or projector selectively cures the resin, layer by layer, creating highly detailed and precise models. These resins can be specialized for different applications, such as standard resins for general purposes, castable resins for jewelry, flexible resins, and tough resins for engineering prototypes, where intricate designs and smooth surfaces are essential.

3. Selective Laser Sintering (SLS):

Selective Laser Sintering (SLS) is a powder-based 3D printing technique commonly used in industrial settings. It employs a high-power laser to fuse powdered materials, such as nylon, polyamide, TPU, and metal powders like aluminum, titanium, and stainless steel, into a solid structure. Unlike FDM and SLA, SLS doesn't require support structures, making it suitable for complex geometries and batch production.

4. Digital Light Processing (DLP):

Digital Light Processing (DLP) is similar to SLA, but instead of using a laser, it employs a digital light projector to cure the resin. DLP offers faster print times compared to SLA due to its ability to cure entire layers simultaneously. The range of materials is similar to SLA, including standard resins for general use, castable resins, flexible resins, and engineering-grade resins.

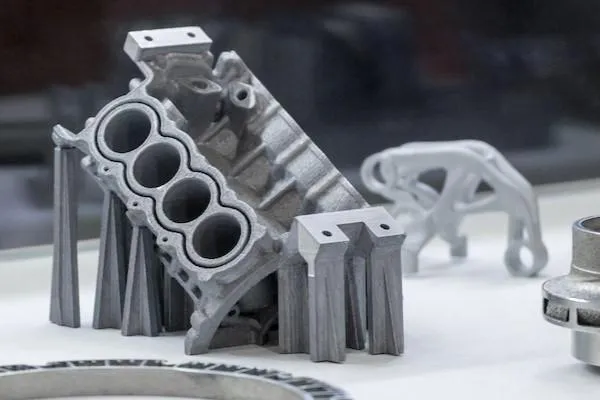

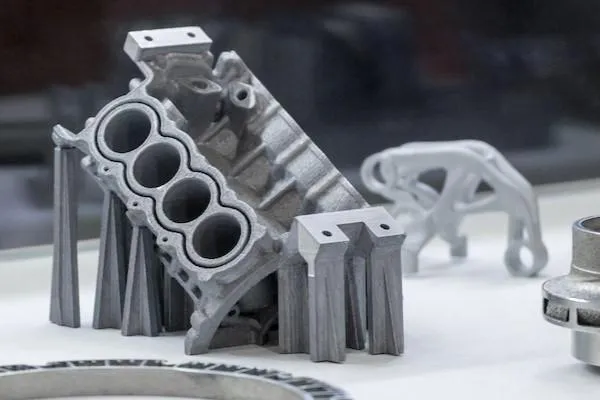

5. Selective Laser Melting (SLM) and Electron Beam Melting (EBM):

Selective Laser Melting (SLM) and Electron Beam Melting (EBM) are metal 3D printing processes used primarily in the aerospace, automotive, and medical industries. SLM uses a high-power laser to melt and fuse metal powder particles together, while EBM employs an electron beam for the same purpose. Some of the metal powders used, include stainless steel, aluminum, titanium, Inconel, and cobalt-chrome alloys. These technologies allow for the creation of strong, complex metal components with precise specifications.

6. Binder Jetting:

Binder Jetting is an additive manufacturing technique that uses a binder to selectively fuse layers of powder material together. Once a layer is complete, a new layer of powder is spread, and the process repeats. Binder Jetting can work with various materials, including metals like stainless steel, bronze, and tungsten, as well as ceramics and sand making it valuable in creating functional prototypes, architectural models, complex metal parts, and intricate sand molds for casting applications.

7. Large-scale Additive Manufacturing (LSAM) or Concrete 3D Printing:

This technology allows for the construction of large, durable structures using concrete or other cementitious materials, like hempcrete. Concrete 3D printing typically involves the extrusion of a special concrete mixture through a nozzle, layer by layer, to build up the desired object or structure. The printer's design may vary depending on the specific application and scale of the project. For instance, some concrete 3D printers are mounted on robotic arms to enable printing of complex shapes and structures.

The advantage of using 3D printing for concrete construction is its potential to reduce material wastage, construction time, and labor costs, making it an appealing option for building affordable and sustainable housing, infrastructure, and architectural elements. The concrete used in 3D printing is specially formulated to be flowable enough for extrusion while maintaining structural integrity after curing. Reinforcement materials, such as steel bars or fibers, may also be integrated into the concrete during the printing process to enhance the strength and durability of the printed structures.

Hempcrete is a bio-composite material made from the inner woody core of the hemp plant mixed with a lime-based binder. It is an environmentally friendly and sustainable alternative to traditional concrete. Hempcrete can be used as a building material in conjunction with certain types of 3D printing techniques. It can be used as a 3D printed wall, just like concrete, where you still need reinforcements, like steel rebar or other fibers, or it can be used to fill voids or gaps within 3D-printed structures, providing additional insulation, structural support, and enhancing the properties of the wall.

hempcrete's a lightweight material with excellent thermal properties, providing natural insulation and regulating temperature and humidity within buildings. The use of hempcrete with 3D printing can contribute to more sustainable construction practices, as hemp is a fast-growing, renewable resource that requires minimal water and pesticides to cultivate. Additionally, hemp absorbs carbon dioxide from the atmosphere during its growth, making it a carbon-negative material when used as a building component.

Clay 3D printers, also known as ceramic 3D printers or clay extruders, are specialized 3D printing machines designed to work with clay-based materials. These printers enable artists, designers, and architects to create intricate ceramic objects and sculptures with ease. Clay printers operate on a similar principle to other additive manufacturing methods. They use a syringe or nozzle to extrude clay in a controlled manner, layer by layer, to build up the desired shape. The clay is usually in a semi-liquid form, allowing it to be easily extruded and deposited in precise patterns. Some applications of Clay 3D Printing include Art and Sculpture, Architecture, like roof shingles, Ceramics and Tableware, like cups and plates, and even in Education, teaching students about digital fabrication and new applications of clay components due to easier manufacturing of complex geometries.

Concrete 3D printing has gained significant attention in recent years, and ongoing research and development are continuously expanding its capabilities and applications in the construction industry. As this technology continues to evolve, it holds the potential to revolutionize the way we build our cities and structures, offering more sustainable and innovative solutions for the future.

The world of 3D printing offers a vast array of technologies, each with its strengths and applications. From affordable FDM printers suitable for hobbyists to high-end SLS and SLM machines transforming industrial manufacturing, 3D printing continues to push the boundaries of what's possible. It's essential to note that the range of materials available for each 3D printing process may vary based on the specific printer and manufacturer. Understanding the different types of 3D printing technologies allows you to make informed decisions when choosing the best method for your specific project needs. Advancements in technology continue to expand both, the variety of materials that can be used in 3D printing and the printing processes themselves, providing even more opportunities for innovation and creativity across different industries. Embrace the creative possibilities that come with 3D printing advancements, and let your imagination take flight in this ever-evolving realm of innovation!

AI TECHNOLOGIES

Unveiling the 3D Printing Wonderland: A Journey Through Diverse Dimensions!

"Creativity is piercing the mundane to find the marvelous."-Bill Moyers

Welcome to the world of 3D printing, also known as additive manufacturing, a revolutionary technology that has transformed the way we design, create, and manufacture objects while opening up new possibilities for innovation. This blog post serves as your comprehensive guide to understanding the different types of 3D printing technologies and their applications. From basic hobbyist models to advanced industrial systems, let's dive into the diverse world of 3D printing.

1. Fused Deposition Modeling (FDM):

Fused Deposition Modeling (FDM) is one of the most popular and accessible 3D printing methods. This technique involves melting a thermoplastic filament and extruding it layer by layer to build the desired object. some of the thermoplastic filaments include PLA, ABS, PETG, TPU, PVA, and more. FDM printers are widely used for rapid prototyping, DIY projects, and educational purposes due to their affordability and ease of use. However, they may have limitations in producing high-resolution and intricate models.

2. Stereolithography (SLA):

Stereolithography (SLA) was one of the first 3D printing technologies invented. SLA printers utilize a liquid photopolymer resin that solidifies when exposed to UV light. A UV laser or projector selectively cures the resin, layer by layer, creating highly detailed and precise models. These resins can be specialized for different applications, such as standard resins for general purposes, castable resins for jewelry, flexible resins, and tough resins for engineering prototypes, where intricate designs and smooth surfaces are essential.

3. Selective Laser Sintering (SLS):

Selective Laser Sintering (SLS) is a powder-based 3D printing technique commonly used in industrial settings. It employs a high-power laser to fuse powdered materials, such as nylon, polyamide, TPU, and metal powders like aluminum, titanium, and stainless steel, into a solid structure. Unlike FDM and SLA, SLS doesn't require support structures, making it suitable for complex geometries and batch production.

4. Digital Light Processing (DLP):

Digital Light Processing (DLP) is similar to SLA, but instead of using a laser, it employs a digital light projector to cure the resin. DLP offers faster print times compared to SLA due to its ability to cure entire layers simultaneously. The range of materials is similar to SLA, including standard resins for general use, castable resins, flexible resins, and engineering-grade resins.

5. Selective Laser Melting (SLM) and Electron Beam Melting (EBM):

Selective Laser Melting (SLM) and Electron Beam Melting (EBM) are metal 3D printing processes used primarily in the aerospace, automotive, and medical industries. SLM uses a high-power laser to melt and fuse metal powder particles together, while EBM employs an electron beam for the same purpose. Some of the metal powders used, include stainless steel, aluminum, titanium, Inconel, and cobalt-chrome alloys. These technologies allow for the creation of strong, complex metal components with precise specifications.

6. Binder Jetting:

Binder Jetting is an additive manufacturing technique that uses a binder to selectively fuse layers of powder material together. Once a layer is complete, a new layer of powder is spread, and the process repeats. Binder Jetting can work with various materials, including metals like stainless steel, bronze, and tungsten, as well as ceramics and sand making it valuable in creating functional prototypes, architectural models, complex metal parts, and intricate sand molds for casting applications.

7. Large-scale Additive Manufacturing (LSAM) or Concrete 3D Printing:

This technology allows for the construction of large, durable structures using concrete or other cementitious materials, like hempcrete. Concrete 3D printing typically involves the extrusion of a special concrete mixture through a nozzle, layer by layer, to build up the desired object or structure. The printer's design may vary depending on the specific application and scale of the project. For instance, some concrete 3D printers are mounted on robotic arms to enable printing of complex shapes and structures.

The advantage of using 3D printing for concrete construction is its potential to reduce material wastage, construction time, and labor costs, making it an appealing option for building affordable and sustainable housing, infrastructure, and architectural elements. The concrete used in 3D printing is specially formulated to be flowable enough for extrusion while maintaining structural integrity after curing. Reinforcement materials, such as steel bars or fibers, may also be integrated into the concrete during the printing process to enhance the strength and durability of the printed structures.

Hempcrete is a bio-composite material made from the inner woody core of the hemp plant mixed with a lime-based binder. It is an environmentally friendly and sustainable alternative to traditional concrete. Hempcrete can be used as a building material in conjunction with certain types of 3D printing techniques. It can be used as a 3D printed wall, just like concrete, where you still need reinforcements, like steel rebar or other fibers, or it can be used to fill voids or gaps within 3D-printed structures, providing additional insulation, structural support, and enhancing the properties of the wall.

hempcrete's a lightweight material with excellent thermal properties, providing natural insulation and regulating temperature and humidity within buildings. The use of hempcrete with 3D printing can contribute to more sustainable construction practices, as hemp is a fast-growing, renewable resource that requires minimal water and pesticides to cultivate. Additionally, hemp absorbs carbon dioxide from the atmosphere during its growth, making it a carbon-negative material when used as a building component.

Clay 3D printers, also known as ceramic 3D printers or clay extruders, are specialized 3D printing machines designed to work with clay-based materials. These printers enable artists, designers, and architects to create intricate ceramic objects and sculptures with ease. Clay printers operate on a similar principle to other additive manufacturing methods. They use a syringe or nozzle to extrude clay in a controlled manner, layer by layer, to build up the desired shape. The clay is usually in a semi-liquid form, allowing it to be easily extruded and deposited in precise patterns. Some applications of Clay 3D Printing include Art and Sculpture, Architecture, like roof shingles, Ceramics and Tableware, like cups and plates, and even in Education, teaching students about digital fabrication and new applications of clay components due to easier manufacturing of complex geometries.

Concrete 3D printing has gained significant attention in recent years, and ongoing research and development are continuously expanding its capabilities and applications in the construction industry. As this technology continues to evolve, it holds the potential to revolutionize the way we build our cities and structures, offering more sustainable and innovative solutions for the future.

The world of 3D printing offers a vast array of technologies, each with its strengths and applications. From affordable FDM printers suitable for hobbyists to high-end SLS and SLM machines transforming industrial manufacturing, 3D printing continues to push the boundaries of what's possible. It's essential to note that the range of materials available for each 3D printing process may vary based on the specific printer and manufacturer. Understanding the different types of 3D printing technologies allows you to make informed decisions when choosing the best method for your specific project needs. Advancements in technology continue to expand both, the variety of materials that can be used in 3D printing and the printing processes themselves, providing even more opportunities for innovation and creativity across different industries. Embrace the creative possibilities that come with 3D printing advancements, and let your imagination take flight in this ever-evolving realm of innovation!

To Get in Touch

Contact Me.

Support@terranaut.net

+1 (737)250-0200

3571 Far West Blvd #3481

Austin, TX 78731

support@terranaut.net

+1 (737)250-0200

3571 far West Blvd #3481

Austin, TX 78731

Copyright 2023 Your Company All rights reserved